VILLIERS Motorcycle Manual PDF

History of Villiers Motorcycles

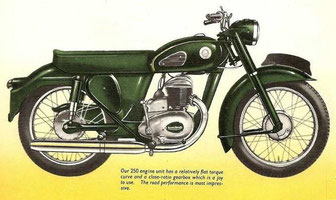

A VILLIERS Motorcycle Manual PDF is above the page.

1880s John Marston's Sunbeam cycle had become extremely successful, by relying on high quality of production and finish. But Marston was dissatisfied with the pedals on his machines, which he bought in.

In 1890, he dispatched his son Charles Marston to the USA on a selling trip but included in his instructions that he must discuss pedal engineering with Pratt and Whitney in Hartford,

Connecticut and come back with a high class pedal and the machinery for making it. Charles has said that the Villiers Engineering Co was "the ultimate fruit" of his trip to the USA. He was impressed by the production system and the labour saving devices he saw there.

He pointed out that "it was not possible to develop these at Sunbeamland, which had long been working on another plan, but it was possible to start them in a new factory".

1898 As a result of the tour John Marston bought a small Japanning works in Villiers Street, Wolverhampton, that had belonged to Edward Bullivant. Under the direction of Charles, the new company made cycle parts for the Sunbeam cycle.

1902 John Marston sold the company to his son Charles for £6,000 on a loan against future profits. Secondly, it developed and patented the cycle free-wheel, which every cycle manufacturer required. The production of free wheels reached its peak just after WWII, as the company produced 80,000 per week or 4 million per year.

1912 Early in the year they introduced their first motor cycle engine, an inlet over exhaust 350cc four stroke with a built in two speed gearbox and clutch but it was considered too A complex and was not a success.

1912 At the end of the year they introduced their first two-stroke engine with a 269cc unit. This engine was designated the Mark I and given the code 'O'.

The cylinder had a fixed head and the bearings for the crankshaft and small end were made of phosphor-bronze while the big end a roller bearing.

The piston was a deflector head type made in cast iron.

The exhaust pipe and expansion box were made in aluminium. The lubrication system was by hand pump from the oil tank, which was built alongside the petrol tank.

The oil was passed through a drilled front crankcase bolt into the crankcase where oil-ways fed it to the bearings.

Surplus oil was splashed onto the walls where it was picked up by the incoming petrol vapour and taken to the upper cylinder.

1912 Situated on a half acre site and employed 20 men

1914 Listed under Cycle Manufacturers as Villiers Cycle Co and under Cycle Fittings Manufacturers as Villiers Cycle Component Co both of Upper Villiers Street.

1916 Introduced the Mark II with changes to the exhaust system which was now made in steel and in the method of holding the exhaust to the cylinder

1961 Manufacturers of internal combustion engines, including the Villiers 2-stroke and 3-stroke light internal combustion engine. Also manufacture cycle components, freewheels, magnetos, and carburettors.

1962 The company was claiming that: "jointly, the two companies produce a vast range of two-stroke and four-stroke petrol engines and four-stroke diesel engines from 1/3rd to 16 b.h.p.

These are the engines which power many of Britain's two-stroke motorcycles, scooters and three-wheelers and the great majority of the motor mowers, cultivators, concrete mixers, generating sets, elevators, pumping sets. etc."

1965 The company was taken over by Manganese Bronze Holdings.

1966 Together with AMC, the company became part of Norton-Villiers). At this point, Villiers stopped supplying engines to outside companies.

Production of the Villiers engine closed in the UK, but continued in Madras, India.

1966 Villiers Tool Development Ltd renamed Viltool Ltd at Wednesfield, Shropshire, specialising in transfer machinery for production lines; turnover had doubled in a year.

1968 Manganese Bronze Holdings sold its 70 percent interest in Viltool to the Snyder subsidiary of the Synder Corporation of the USA.

In 1999 Villiers Plc acquired the healthcare company Ultramind and renamed the company Ultrasis.